More 3D Printing Enclosure Upgrades

August 2021

Air filtration, heat and humidity management are an important part of maintaining high quality 3D prints. All through the year the humidity in Brisbane can be quite high so it’s important to control the climate in the workshop.

An air filtration unit has been installed in the enclosure and a dehumidifier is on its way which is designed to work in tandem with the filter.

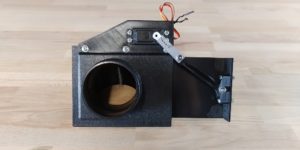

The intention is to have an Arduino controller with a touchscreen that enables the three compartments in the enclosure to be filtered independently and shut off when not in use. The touchscreen allows control of the blast gates shown in the picture gallery below to seal any section of the enclosure that isn’t in use. A temperature and humidity sensor in each compartment will assess the conditions and the Arduino will automatically route humid air through the dehumidifier/heater and filter.

Because of the unusual size of the blast gates, the ducting needed to be designed from scratch in CAD and 3D printed. The plus side of this is that everything fits perfectly and was able to be installed without issue.

One of the rear ducting pieces on the printer

Pingback: June 2021 – Enclosure upgrades – Lannix 3D