A Few Words About

What We Do

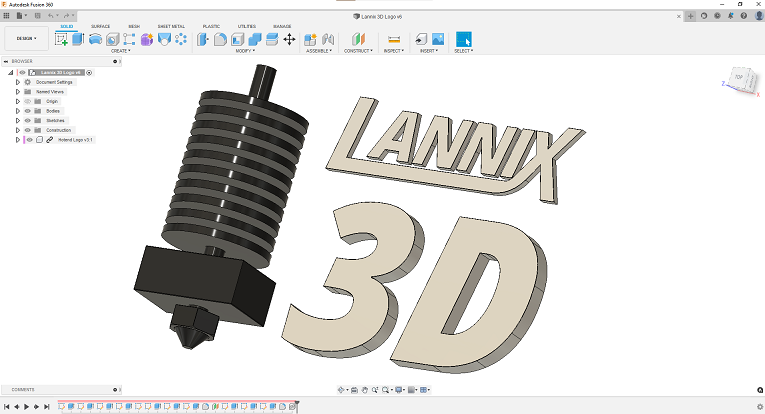

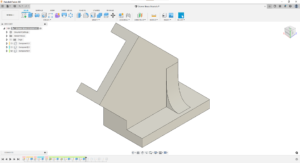

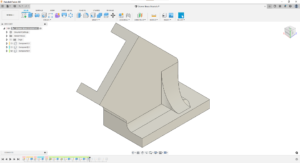

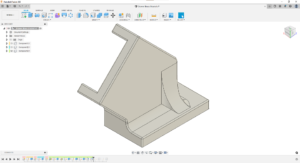

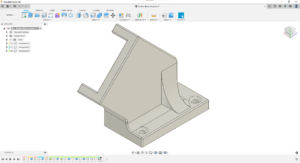

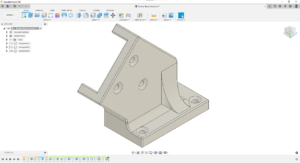

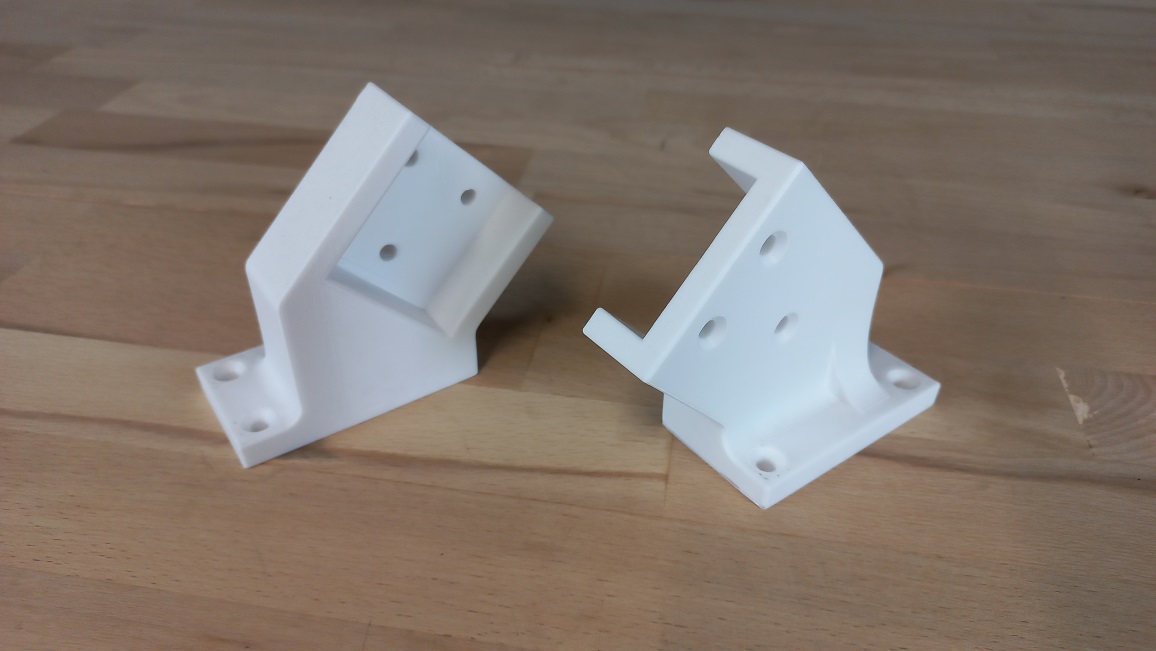

Computer Aided Design (CAD)

We offer CAD services designed to compliment the 3D printing side of the business, having over nine years experience using various CAD software suites such as SolidWorks, Inventor and Fusion 360.

We also undertake CAD jobs unrelated to 3D printing such as steel fabrication/manufacturing drawings and creating DXFs or DWGs for laser cutting processes.

We understand that CAD can be daunting for the uninitiated so we’re happy to help out if needed. All we need to create a part for you is a sketch with some basic dimensions and a description of the part’s application.

Designing for 3D printing is a unique skill where the designer must take into account any expected loads on the part when in use and consider the printing orientation to maximise strength.

Feel free to contact us for your CAD needs. We believe communication is the key to achieving a happy outcome for all parties involved.

3D Printing

We now have nine 3D printers ready to produce parts for our customers. We have spent the time to calibrate each machine for optimal performance since every filament used requires fine-tuning to achieve the best results.

We use Australian made filament sourced from Aurarum in Melbourne and have found it to be outstanding quality.

At this stage we use two different types of filament which have their own unique properties.

PLA

PLA or Polylactic acid filament is a general purpose material best suited when high strength characteristics and high quality appearance is required. It is easy to work with and inexpensive. It is made from renewable, organic sources such as corn starch or sugar cane and can be recycled easily.

PETG

PETG or Polyethylene terephthalate glycol is similar to the plastic that soft drink bottles are made from but with glycol added to aid in the 3D printing process.

We have found that PETG is better for use in higher temperature applications such as car interior parts but has the downside of being slightly more brittle when compared to PLA.

The video below is great for explaining the effects of filament material and printing orientation on part strength, presented from an engineering point of view.

3D printed part designed using cAD

Coming soon - Other filaments

There are many other filaments around all with their unique advantages and disadvantages. Our long-term plan is to make more options available in future if there is a demand for it.

Trials are taking place with Nylon, Carbon Fibre and flexible materials but they won’t be made available until consistent results can be achieved.

Future Plans

3D Scanning

Recently, Lannix3D has acquired a 3D scanner and trials are taking place to determine whether there is a worthwhile business case for offering 3D scanning as a service. Once trials have successfully been completed, we’ll share some results and see what you think.

Laser Cutting

The 3D printing enclosure has been built to suit the dimensions of a laser cutting machine that we have plans to build in future. Some parts have been acquired and put to the side for the machine but this will be a longer term project and isn’t a high priority at this time.

Online store

Some of the parts we have needed to 3D print to complete our projects could be useful to others. Plans to make them available to anyone interested have prompted us to create an online store to sell them as both 3D printed products or a digital download so that they can be 3D printed at home.

A website has been created already and just needs to be stocked and a procedure put in place to handle payments etc.