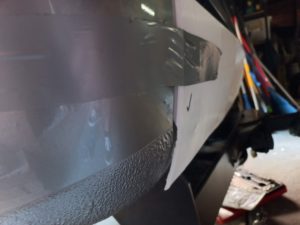

Ford Ranger 3D Printed Prototype Rear Bumper Test Fit

13th July 2022

The first prototype part for our offshoot business collaboration, R-Spec, has been designed and 3D printed using the 3D scans we produced a few weeks ago. My business partner Michael has had this Ford Ranger part in mind for quite some time and has already produced a few parts for his Ranger in his garage from fibreglass. As a proof of concept I thought this bumper would be perfect for developing a 3D scanning/modelling/printing workflow for the business.

Ford Rangers are sold all over the world and are a good looking vehicle. Consequently there are many who have taken to modifying them for looks and performance including Michael.

The 3D printing process took around 35 hours total for all seven parts using the super-speed print setting I’ve developed. The individual pieces were then epoxy glued together as they came off the printers.

The fitment was very close to perfect. The length was right on the money leaving a perfect panel gap. The face of the bumper sat around 5mm proud of the rear quarters so we’ll need to take material away in the design. The number plate needs some extra room to fit properly which can be easily fixed by angling the recess slightly higher than tic currently sits.

We’ve decided to add a few additions to the design after seeing it on the vehicle such as a vertical upright section that covers the spare wheel access hole with a removable cover piece. Openings for the number plate lights are also needed.

Successful test fit of the Ford Ranger custom rear bumper design prototype.

The next step is to make the changes mentioned to the 3D model and 3D print another prototype to confirm we have something ready for mass-production. Once we’re satisfied that we have a perfectly fitting and quality model we’ll search for a manufacturer, hopefully locally, to produce the finished product. In the meantime the admin part of this business needs working out. Web domains have been locked down as well as Facebook and Instagram profiles.

It’s encouraging to see that this workflow can be successful for a small business and we now have high hopes! We’ll keep you posted on the progress of the part.

Until next week…